Die-Cutting for Custom Paper Box

Die-cutting is process where a die is used to cut various custom shapes out of the paperboard and crease various custom folding lines on the paperboard. The die-cutting is an indispensable procedure for your custom paper printed boxes, corrugated printed boxes, rigid paper boxes and custom paper bags.

The E-Flute corrugated mailer box is a typical die-cut paper box, easily assembled without any glue applied. This die-cut corrugated box is flat packed and shipped.

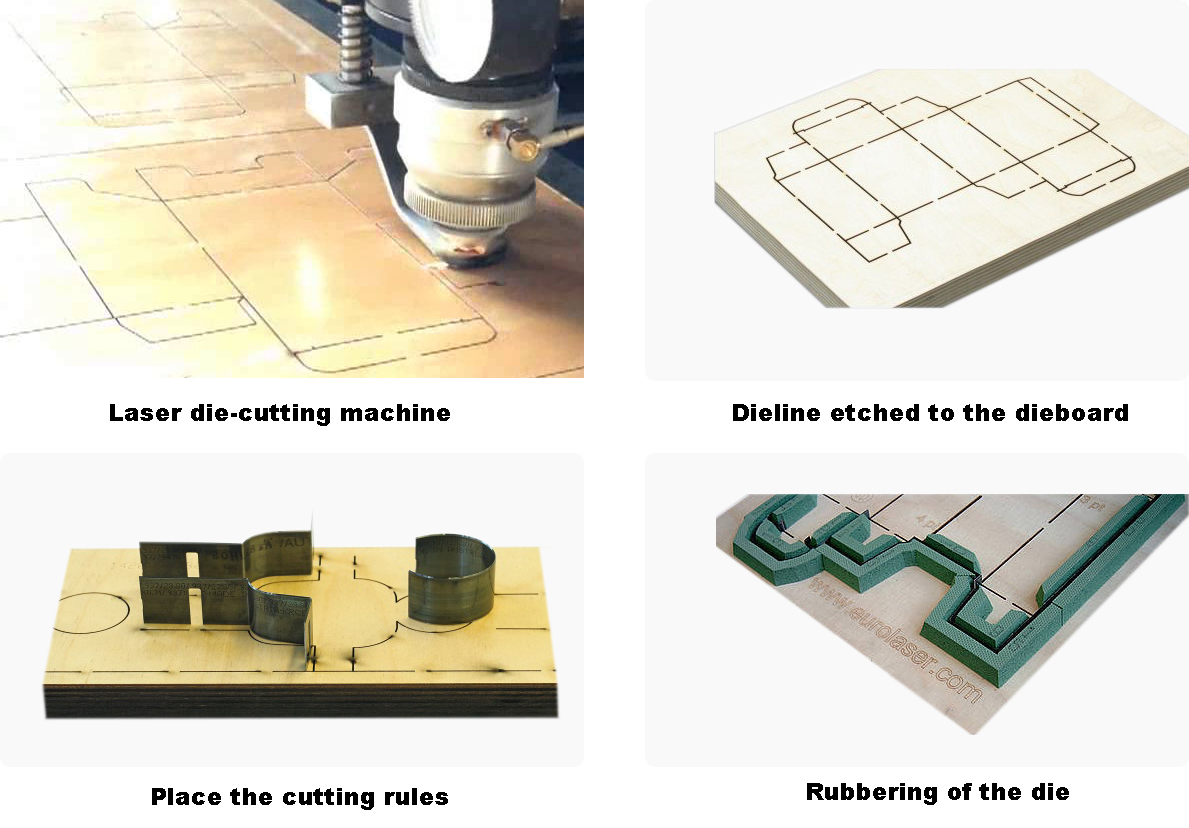

The Die-Cutting Process

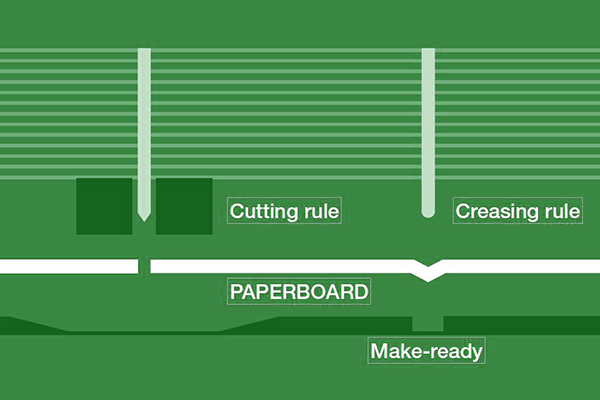

The die consists of the cutting and creasing rules. When performing the die-cutting operation, the die reciprocates up and down towards the paperboard, which is placed on the make-ready. After one cycle the cut paperboard sheet is removed and a new one is fed into the machine.

- Use Artios CAD or AutoCAD to prepare the dieline template on the computer

- Use the laser die-cutting machine to etch the dieline on the die board

- Make the cutting rule and creasing rule by cutting and bending the steel rules manually or automatically, then insert the rules into the dieboard along the well-defined lines

- Place the ejection rubber along the dielines

- Mount the die onto the press machine for the diecutting of the paperboard

Die-cutting Process for Custom Paper Box

Laser cutting is the most elaborate cutting method. This helps us to create intricate details and complex designs for your custom packaging boxes. With the right paperboard, almost any paper box structures can be achieved.

The original design is etched through a copper template, which is positioned over the paperboard. A sharply focused laser beam runs back and forth over the template and wherever there are etched areas, and the laser beam vaporises from the paperboard.

An ejection rubber is used to hold the sheet in a fixed position during cutting and to eject the paperboard blanks from the cutting die. The rubbering of the cutting die plays a very important role for the final product.

Cutting

A properly cut custom paper box should be free from loose fibres to ensure accurate and clean edges.

To achieve debris-free edges, it is important to have sharp, well-adjusted knives and good control of the die-cutting machine. The high force required to cut through has to be well controlled to minimise what we call the “overshot” of the moving die. This is to prevent damaging the knives and degrading the quality of the cuts.

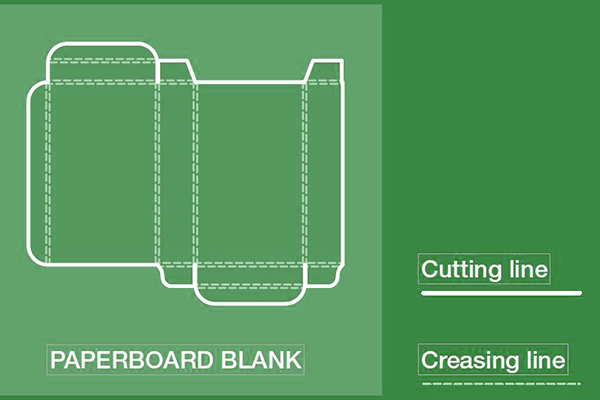

Creasing Line and Cutting Line

Creasing Line and Cutting Rule

Creasing

Creasing is an operation which facilitates the folding mechanism of your custom paper box. During creasing, the paperboard is weakened along well-defined folding lines, which then act as hinges for folding packaging boxes.

The creasing rules are fitted into the die. When performing the creasing operation, the die reciprocates up and down towards the paperboard, which is placed on the make-ready. After one cycle the creased paperboard sheet is removed and a new one is fed into the machine.

The paperboard is creased by being pressed into a groove. The forces created deform the paperboard in a predetermined way and the deformation is permanent. The result is a reduction in the bending resistance of the crease.

Die-Cut Paper Box

Die-cut paper box refers to the folding cartons which can be easily assembled without any glue. They are widely used for corrugated mailer boxes.

Die-Cut Corrugated Mailer Box